5%off Mini Excavator Parts Heavy Duty Earthmoving Bucket for 6-8 Ton Mini Excavator 40 Widteh Bucket, Rock Bucket, Ripper Bucket, HD Bucket, Gp Bucket

Basic Info

| Model NO. | mini bucket |

| Application | Excavator |

| Certification | ISO9001: 2000 |

| Condition | New |

| Product Type | Heavy Duty Bucket |

| Bucket Capacity | 0.1 - 4m3 |

| Bucket Type | Rock Bucket/Standard Bucket/Mini Bucket |

| Machine Brand | Cat, Komatsu, Sany, Hitachi, Doosan, Volvo |

| Excavator Type | Crawler Excavator/Mini Excavator Buckets |

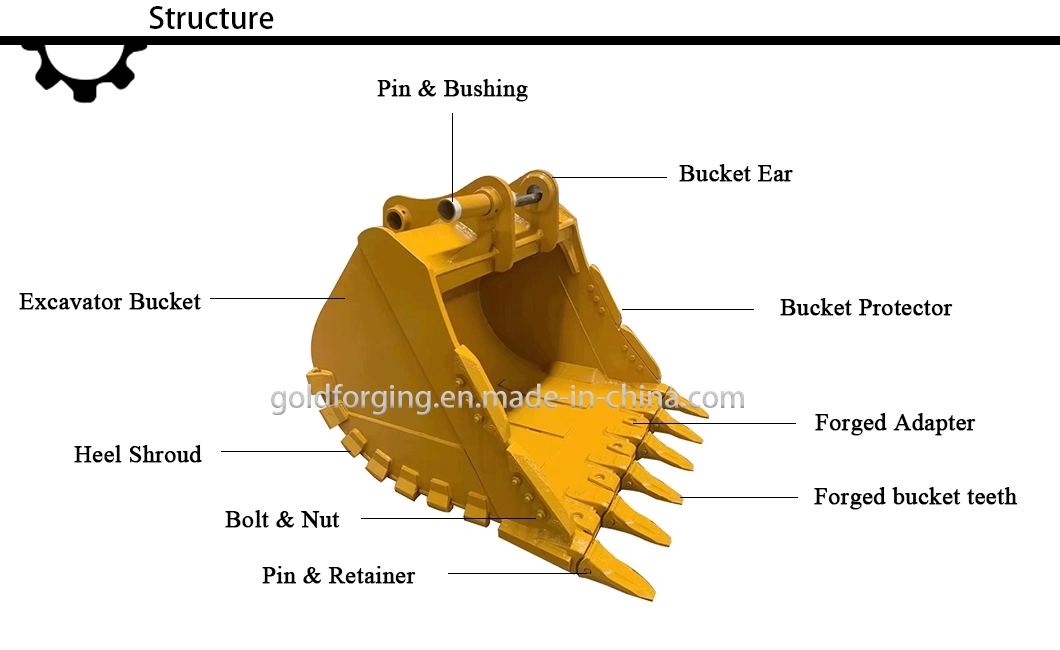

| Bucket Parts | Bucket Linkage, Bucket Teeth and Adapter |

| Bucket Spare Parts | Side Cutter, Bucket Protector, Heel Shroud |

| Color | Customized |

| Service | OEM ODM |

| Cerfitication | ISO9001 |

| Test Report | Provided |

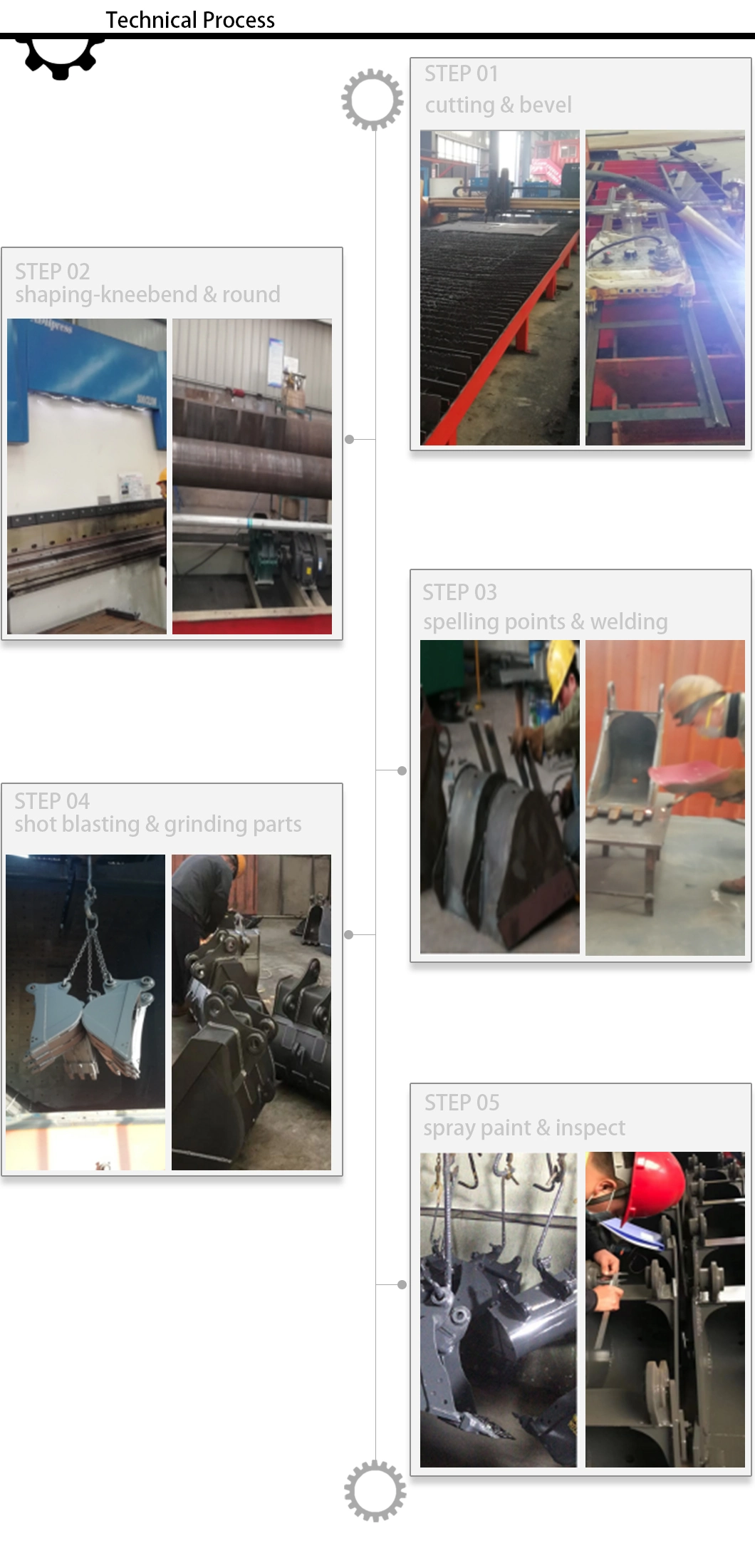

| Process | Welding |

| Deliver Time | 7-10 Days After Contrast Established |

| Working Condition | Iron Ore, Quarry, etc |

| Advantage | Good Mechanical Properties |

| Transport Package | Export Package |

| Specification | Base on drawing |

| Trademark | Gold Forging |

| Origin | Xiamen, China |

| HS Code | 843149 |

| Production Capacity | 3000PCS/Month |

Packaging & Delivery

Package size per unit product 1.00cm * 1.00cm * 1.00cm Gross weight per unit product 1.000kgProduct Description

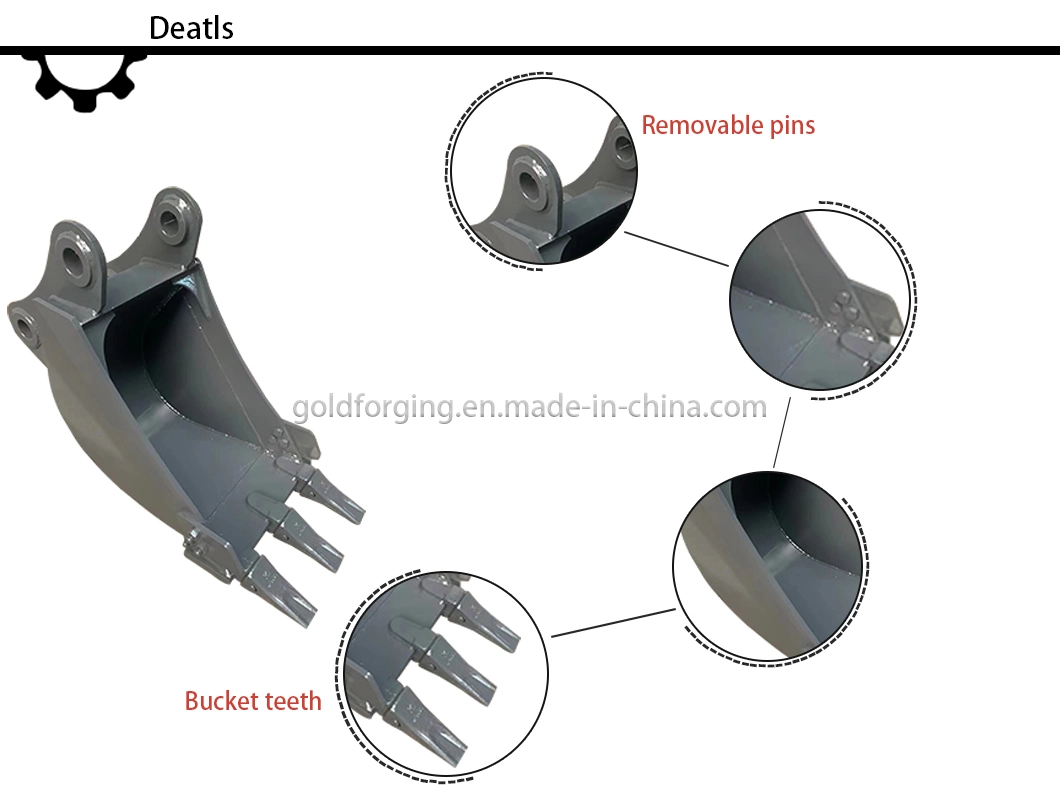

Detailed Photos

We can offer different types buckets for excavator, like Mini bucket, Standard bucket, Heavy duty bucket, Skeleton Bucket...

Product Parameters

| Excavator Bucket Serie | ||||

| Type | Material | Performance | Application | Suitable Brands |

| Rock Bucket | High-strength wearable steel plate, such as Q355, Q460, Q550, NM400, Hardox400. Or as per your different requirements or drawings. | Compared with the reinforced bucket, the rock bucket is more robust and reliable, the thicker wear plate can extend service life in harsh working conditions. | Suitable for high wear occasions, such as gravel, granite, excavating soil mixed with hard rocks and wind fossils. | Cat, Komatsu,Hitachi, Sany, Volvo,Hyundai, LIUGONG, Kubota, Kobelco, Doosan, Daewoo, Sunward.... |

| Standard Earthwork Bucket | It adopts high strength structural steeel and high quality bucket tooth seat, which saves operation time and improve efficiency. | Used in excavation of clay, loading sand, soil and gravel, and quarries, iron ores. | ||

| Mini Bucket | It has the characteristics of compact, flexible, multi-function and high efficiency. low emission,low fuel consumption and convenient maintenance. | Mainly used in constructions of piplelines, river, ponds, ditches; foundation construction, earthwork and other municipal construction. | ||

| Note: Please choose the bucket based on the construction condition, avoid reducing the service life or damage. | ||||

Bucket Production Process

Company Profile

Establised in 2014, Gold Forging has more than 8 years industry experience, we continuously introduce new equipment, improve products quality. Our factory bucket working with LIUGONG since 2018, and keep good relationship with them until now.Complete training system, strict quality requirements, to ensure high quality of products and our products have won unanimous praise from customers.Strong R&D Team can offer customized service to our customer, and our bucket and bucket parts can suitable for Cat, Komatsu,Hitachi, Sany, Volvo,Hyundai, LIUGONG, Kubota, Kobelco, Doosan, Daewoo, Sunward....

FAQ

1. You are a trader or a manufacture?

We are an industry and trade integration business, our factory located in Quanzhou ,and our sales department is in City centre of Xiamen.

2. How can I be sure the part will fit my excavator?

Give us correct model number/machine serial number/ any numbers on the parts itself. Or measure the parts give us dimension or drawing.

3. How about the payment terms?

We usually accept T/T or L/C. other terms also could be negotiated.

4. What is your minimum order?

It depends on what you are buying. Normally, we don't have MOQ request.

5. What is your delivery time?

If don't stock in factory : 20 days . If there are any parts in stock , our delivery time is only 0-7 days.

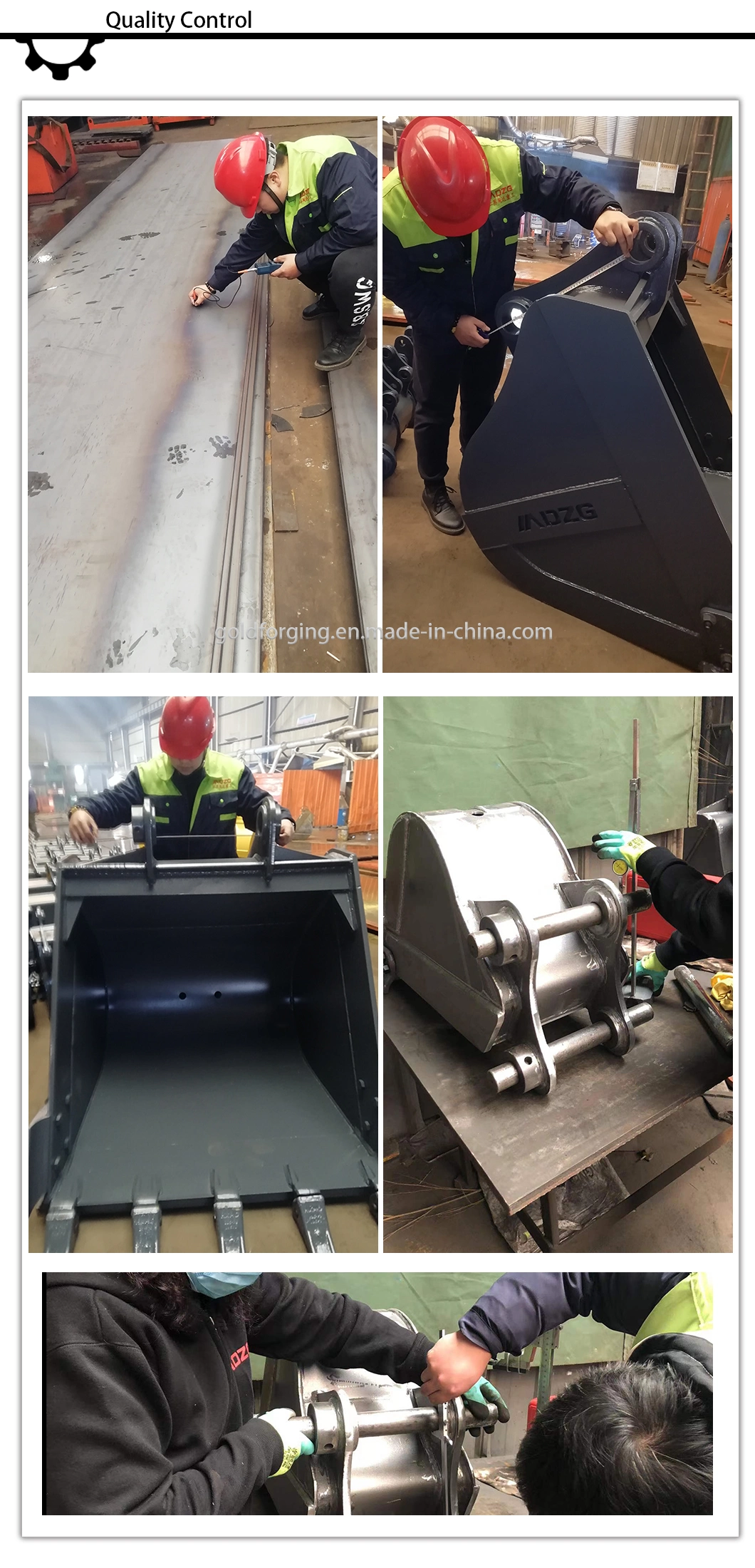

6. What about Quality Control?

We have a perfect QC system for the perfect products. A team who will detect the product quality and specification piece carefully, monitoring every production process until packing is complete, to ensure product safety into container.

7. Can offer the sample ?

For forged bucket teeth we can offer free sample, but the clients need bear the freight.